Machine Learning and AI for revolution of Tech Companies are changing and streamlining businesses.

The logistics industry should efficiently transport products across various states and countries so the sector can contribute to the economy and increase bilateral trade. AI optimizes the route and automates vehicles, helping to transport products smoothly and efficiently to various places.

The logistics industry uses the whole supply chain process, from procuring raw materials to transporting and distributing them. Using AI-powered logistics reduces operation costs and increases productivity and seamless operations. Also, automating the process reduces errors and delays in transporting products.

Here, in detail, take the overview of AI logistics and the Impact of AI in logistics industry. It also provides information on the role of artificial intelligence technologies in the logistics industry and how AI is implemented in the logistics industry.

What is AI in logistics?

In logistics, AI uses algorithms and machine learning to automate tasks and optimize logistics processes. Also, AI helps predict future production, customer demand forecasts, and transportation routes, leading to efficient resource use and reduced costs.

AI is using self-driving drones and trucks to carry products from one place to another which is reducing the cost and increasing efficiency. Furthermore, it eliminates the need for drivers for the logistics process.

Impact of AI on the logistic Industry

Consumer demand is constantly changing, so it is essential to digitalize the logistics process. AI and machine learning used in supply chain management bridge the gap and provide error-free supply chain management from sourcing the raw material to delivering the end product to the customer. Additionally, according to the statistics, The global AI in logistics industry was valued at USD 7.96 billion in 2022. Projections indicate that it is poised to reach $19.89 billion by 2031, representing a substantial growth trajectory at a CAGR of 45.93% during the forecast period from 2023 to 2031. Let’s look at the impact of AI on the logistics industry.

Predictive analysis

AI helps analyze historical data and predict the demand for products, which helps maintain the inventory of products and optimize logistics operations. The optimizing operations reduces the risks and increases the profit of the business. Additionally, predictive analysis helps strategically plan shipments through optimized routes.

Computer vision

In AI, machine learning algorithms allow AI to sort and segregate the packages for damages, faults and more. This technique is the basis of integrating computers with cameras and processing. Also, AI helps quickly load and offload packages with the help of robots in warehouses. All the activities AI is doing save time and cost of human labor.

Autonomous Vehicles

AI helps forecast the fastest route to the destinations and deliver the product within a minimum time. Also, package damage is reduced as AI can analyze the data quickly, enhancing experience and profitability.

Big Data

AI can handle large volumes of data in logistics effectively and efficiently. Also, analysis helps you stay ahead of the curve by predicting risks like bad weather conditions, broken roads, etc.

Ready to take your logistics to the next level? ViitorCloud offers customized AI solutions designed to streamline your operations and drive growth.

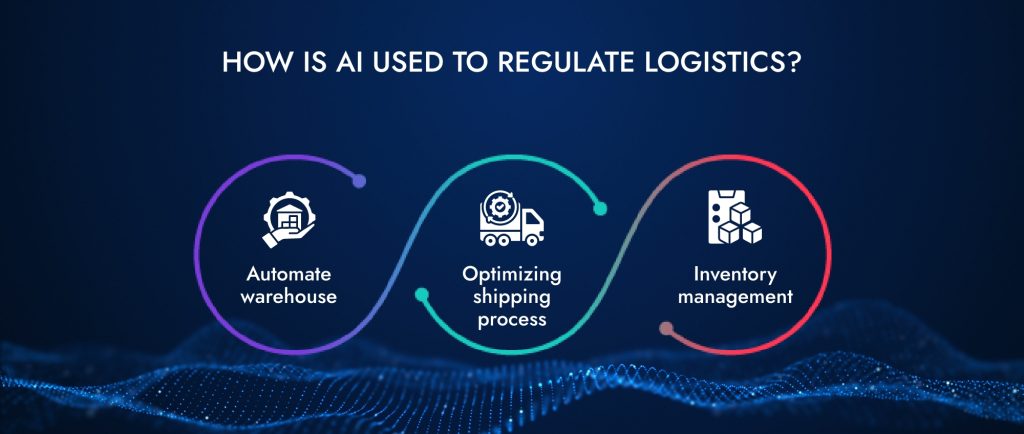

How is AI used to regulate logistics?

AI helps in regulating the logistics process. The process where the company ensures the product in demand is manufactured timely and distributed efficiently. Because of this, transportation costs are reduced, and money is saved.

Let us understand in detail How AI is used in logistics.

1. Automate warehouse

One of the global e-commerce stores, Amazon, requires quick and intricate logistics solutions, so they speed up their money to get advanced AI and robotics to make automated warehouses. Amazon invests in AI-powered process automation warehouses, recruiting top experts, buying businesses, etc. Depending on your business size and type, you can use AI in a warehouse in the logistics industry. It is the way Amazon uses AI logistics automation in business.

2. Optimizing shipping process

AI helps forecast efficient shipping routes, which provides cost-effective and faster shipping routes using the machine graph theory. It is helpful for businesses that have various clients because shipping route costs will be low, and it provides maximum reach to clients. Additionally, AI can forecast traffic on roads and busy days on roads. It is the way AI for logistics efficiency improves in operation.

3. Inventory management

A company can devote full attention to selling the goods instead of inventory management, as AI helps in inventory management. AI can analyze large amounts of customer data, understand customer preferences and interests, and determine which product demand will be in the market. As a result, the company can prepare the product in advance and stock the product appropriately rather than depending on real-time demand.

The role of AI in logistics and supply chain industries

AI technology is transforming every industry, and logistics is also part of it. In logistics, AI helps optimize operations, automate route and demand forecasts, and increase efficiency.

Let’s understand the role of AI in logistics and supply chain industries.

1. Demand forecast and inventory management

AI helps analyze historical data, market trends, and external factors to forecast product demand, optimize inventory, reduce carrying costs, minimize stockouts, and improve customer satisfaction.

2. Route optimization and fleet management

AI identifies traffic patterns, weather conditions, and delivery priorities to optimize the route. Also, fleet management is possible through monitoring vehicle conditions, predicting maintenance, and automated scheduling.

3. Warehouse automation

ML algorithms analyze data from cameras, sensors and RFID tags to optimize storage places, increase picking accuracy and reduce operation costs. It is the way AI logistics automation is used in warehouses.

4. Customer experience

Predictive analytics helps identify delivery issues, reduce delays, reroute shipments and improve customer experience. Al delivery tracking system provides accurate information on their order, which builds trust.

5. Risk management

AI helps detect emerging risks, such as supplier delays, natural disasters, or geopolitical events. This allows companies to take proactive measures and minimize disruptions to reduce risks.

Empower your logistics and supply chain operations with AI-driven senses and automation. ViitorCloud provides industry-leading AI services that deliver measurable results.

How do we implement AI solutions in supply chain and logistics?

Implementing AI solutions in supply chain and logistics involves several steps, from data collection to training models. Let’s understand in detail.

1. Define objective and scope

The objective of implementing AI in business should be clear. Also, it is essential to identify specific areas where AI can provide value, such as route optimization, inventory management, demand forecasting, and predictive maintenance.

2. Data collection

The collection of the right data is essential for the business as it helps with decision-making. You can gather the relevant data from sources such as historical sales, weather, transportation, and other relevant information. Also, ensure data quality is good.

3. Data integrate

After data collection, integrate the data from different sources to build a unified dataset. Technologies like transform and load processes, extract, clean, and merge the data are used for that.

4. Choose AI technologies

After data integration, select the right AI technology based on your objective. The common technologies are deep learning, machine learning, computer vision and natural language processing. Also, depending on the complexity of business requirements, choose between pre-existing AI-powered logistics solutions or build custom models.

5. Model development

After choosing AI technology, develop a model for supply chain and logistics. The models include route optimization algorithms, demand forecasting models, and predictive maintenance models. Also, use frameworks such as Cikit-learn for traditional machine learning and TensorFlow for deep learning.

6. Training

After model development, divide the dataset into testing and training sets to check the performance. Also, train your model using hyperparameters and training data to achieve optimal performance. Additionally, validate the model using testing datasets.

7. Integrate with existing systems

Integrate AI model into existing logistics and supply chain systems. Also, collaborate with IT teams and deploy APIs to communicate between systems.

8. Monitoring and maintenance

Monitor the model system continuously, and if you find any issues, make improvements. Also, regular update models use new data to ensure it remains relevant and accurate.

9. Scale and optimize

Once operating AI solutions, consider it to scale in the logistics supply chain. Also, optimize algorithms based on feedback and performance evaluations.

10. Compliance and security

AI compliance should be implemented with regulations, especially concerning data privacy and security. Also, AI provides security to sensitive data and AI models.

Transform your logistics with AI. ViitorCloud offers AI solutions to streamline supply chain operations, enhance efficiency, and reduce costs.

Large companies and startups implementing AI in logistics

AI in business helps to solve complex problems using technology. According to recent surveys, 36% of businesses of different sizes have implemented AI for logistic processes and supply chains. AI is the key component in the logistics industry to make work efficient and cost savings.

Amazon

The e-commerce leader company Amazon uses AI in its logistics operations. It helps with accurate demand forecasting and optimizes inventory management. Also, AI automates the warehouse system where robots pack, pick, and sort items, which reduces errors and increases efficiency.

ClearMetal

ClearMetal is using AI to improve the efficiency of logistic operations with predictive analysis. The AI algorithms accurately track the shipping of products, predict, and manage the complex dynamic container of logistics. The implementation of AI eliminates unnecessary expenses linked with mismanagement of goods, underutilized shipping containers, and idle assets. It is a clear example of how AI logistics is used to save logistics costs.

Grey Orange

Grey Orange combines robotics with machine learning to pick, sort, and pack goods accurately and quickly. Also, AI automates repetitive tasks, reducing human errors and speeding up the delivery timeline. AI frees human beings from such repetitive tasks so they can focus on strategic areas and operate more efficiently.

Future of AI in the supply chain and logistics industry

The future of AI in the supply chain and logistics will bring big changes in the industry. It will automate vehicles in logistics to increase efficiency in the transportation of goods.

Let’s understand the future of AI in the supply chain and logistics industry.

1. Automates vehicles

The automation of vehicles in logistics will increase in future, leading to more efficient and safe transportation of products. Also, self-driving drones and trucks reduce the need for human drivers and improve the accuracy and speed of deliveries.

2. Increase adoption

The adoption of AI logistics solutions will increase as companies understand the benefits of using AI. The AI in logistics improves efficiency, reduces costs, and enhances customer experience.

3. Predictive analyst

The predictive analyst plays an essential role in the logistics industry. AI tools can analyze large amounts of data to predict customers’ demand, optimize routes and prevent disruptions before they occur. As a result, efficiency increases in the logistics industry and makes work smooth.

4. Provide safety and security

AI uses biometric identification, facial recognition, and machine learning technology to enhance safety and security in the logistics and supply chain industry. It helps in reducing the risk of theft, fraud, and terrorism.

5. Sustainability

AI helps create sustainability in the logistics industry. It helps reduce emissions, optimize routes, and promote efficient energy usage to reduce the industry’s environmental impact.

Epmliment AI to optimize logistics and supply chains for operational excellence and growth. ViitorCloud offers tailored AI solutions to meet your business’s unique needs.

How do ViitorCloud AI services streamline your logistics operations?

AI logistics automation helps in streamline logistics operations by automating vehicles such as trucks and drones. Also, AI analyzes traffic patterns and weather conditions to optimize routes and deliver the product at the right time to customers, which satisfies them. Additionally, the demand forecast of the product helps in stocking the product at a warehouse, which reduces the operation cost in the supply chain.

We, Viitorcloud, an AI development service company, have worked with multiple clients to provide diverse solutions in the digital world, and we are happy to help you in the same way. Our professional experts listen to your problem carefully, understand it, and provide you with solutions that meet your business needs. Contact our AI experts to start or scale your business and streamline the supply chain process with AI in logistics.

Frequently asked questions

The role of artificial intelligence in logistics and supply chain is to forecast the demand for product and inventory management. Also, it helps in warehouse automation, route optimization and fleet management, risk management and customer experience.

Examples of AI that can optimize supply chains are risk management, knowledge capture, supplier selection, inventory optimization, and supplier relationship management. Also, AI-automated vehicles such as drones and trucks reduce the need for human beings.

AI logistics solutions help reduce overhead costs in the logistics industry by identifying cost-effective shipping routes, reducing transportation costs and improving delivery times. Also, AI helps evaluate and manage suppliers and enhance customer experiences.

AI helps reduce costs in the logistics industry by analyzing the data to predict product demand and stock products in the warehouse. Also, optimize routes of roads so timely delivery can take place, which saves time.

The benefits of Artificial intelligence in logistics and supply chain operations are improving warehouse efficiency, reducing operation costs, predicting inventory management, and improving security. Also, provide time delivery of products and forecast the demand for products.