Machine Learning and AI for revolution of Tech Companies are changing and streamlining businesses.

In the dynamic and high-risk world of the oil and gas industry, safety is paramount. Workers often face perilous situations, complex machinery, and challenging environments that require rigorous training and preparedness.

Ensuring the well-being of employees is a top priority, and this is where VR Safety Training solution comes into play.

Let’s explore the various facets of VR safety training solutions for the oil and gas sector, its benefits, applications, challenges, and how to develop and implement VR Safety Training app development.

Overview of the oil and gas industry and its safety challenges

Virtual Reality, or VR, is an immersive technology that transports users to computer-generated environments, providing a realistic and interactive experience solution.

It has gained prominence in numerous industries, including healthcare, education, and entertainment.

From drilling rigs to refineries, employees are exposed to potential risks like fires, explosions, toxic gases, and heavy machinery accidents.

However, VR Training for Safety has proven to be a game-changer in the oil and gas sector, where its applications for safety training are transforming the way workers prepare for the challenges they may encounter.

VR Safety Training app development is non-negotiable due to the potential for catastrophic incidents.

Importance of VR in oil and gas safety training

VR technology is addressing the unique safety training needs of the oil and gas industry.

It offers a practical solution to immerse workers in realistic simulations, enabling them to practice and refine their skills without real-world risks.

The importance of VR in this context cannot be overstated, as it enhances safety measures, minimizes accidents, and ultimately saves lives.

Challenges and solutions of VR in oil and gas safety training

| Challenges and Limitations | Solutions |

| Adoption and Implementation Barriers | Enhanced Learning and Retention |

| Technical Challenges and Integration Issues | Realistic and Immersive Training Scenarios |

| Regulatory Compliance and Certification | Safe and Controlled Environment for Practice |

| Limited Access to Technology and Resources | Reduced Costs and Increased Efficiency |

Real-life example:

There are numerous examples of companies using VR for safety training in the oil and gas industry.

Companies like Shell and BP have implemented VR safety training solution programs, reporting substantial benefits in terms of improved safety records, reduced accidents, and cost savings.

User feedback and satisfaction ratings in these programs have been overwhelmingly positive.

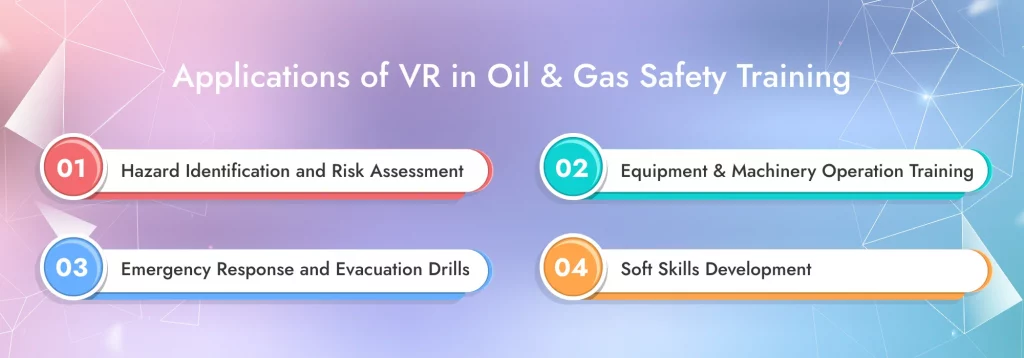

Applications of VR in oil and gas safety training

As we move forward, it is clear that VR has a pivotal role to play in the well-being of the industry and its workers. Some examples of application of VR in Oil and gas safety training are:

Hazard identification and risk assessment

VR training for safety enables employees to identify potential hazards and assess risks in a lifelike environment. This empowers them to proactively mitigate dangers, enhancing overall safety.

Equipment and machinery operation training

Operating heavy machinery and equipment in the oil and gas industry demands precision and skill.

VR simulations allow workers to familiarize themselves with machinery operations without the inherent risks of hands-on training.

Emergency response and evacuation drills

Oil and gas facilities must be prepared for emergency situations.

VR allows for realistic emergency drills, helping employees practice response procedures, evacuation routes, and crisis management.

Soft skills development (communication, leadership, etc.)

In addition to technical skills, soft skills are vital for safety in the industry.

VR can simulate challenging communication and leadership scenarios, helping employees develop the necessary interpersonal skills to manage critical situations effectively.

How to develop and implement a VR safety training solution program

To develop and implement a VR safety training solution program in the oil and gas sector, companies should consider the following steps:

- Assess Needs: Identify specific safety training requirements and areas where VR can make the most impact.

- Select the Right VR Solution: Choose or develop VR training programs that cater to your industry’s specific needs.

- Train and Educate: Provide comprehensive training for employees, ensuring they are comfortable using VR technology.

- Regular Updates: Keep VR simulations and training materials up to date to reflect industry changes and emerging risks.

- Evaluate and Adapt: Continuously assess the effectiveness of VR training, gather feedback, and make necessary adjustments for improvement.

Conclusion

VR is revolutionizing safety training in the oil and gas industry. The benefits are clear, from enhanced learning and risk reduction to improved efficiency and cost savings.

While there are challenges to overcome, the future of VR Safety Training app development in oil and gas safety training is promising.

VR Safety Training Solutions, VR for Safe Work Environments, and VR for oil and gas safety training are no longer just catchphrases; they are vital tools for enhancing safety and protecting lives in this high-risk industry.

Embracing this technology is not just a choice; it’s a responsibility.

Frequently asked questions

VR enhances oil and gas safety by offering immersive, risk-free training scenarios that prepare workers for real-world challenges.

VR can prevent falls in oil and gas by simulating working at heights and helping workers practice safety measures in a safe, virtual environment.

Leading VR safety training solution providers for oil and gas include Honeywell, EON Reality, and Strivr for their tailored safety programs.

Virtual reality is used in safety training by creating lifelike simulations for hazard identification, equipment operation, and emergency response.