Machine Learning and AI for revolution of Tech Companies are changing and streamlining businesses.

Today, Augmented Reality (AR) has emerged as one of the most significant futuristic technologies used across many industries, including engineering. The integration of augmented reality engineering solutions can unlock a realm of possibilities, fundamentally altering how professionals design, construct, and maintain various structures and systems.

AR overlays digital information onto the real world, enabling engineers to visualize and interact with their designs in a more immersive and intuitive way. This can help to improve the accuracy, efficiency, and safety of engineering projects.

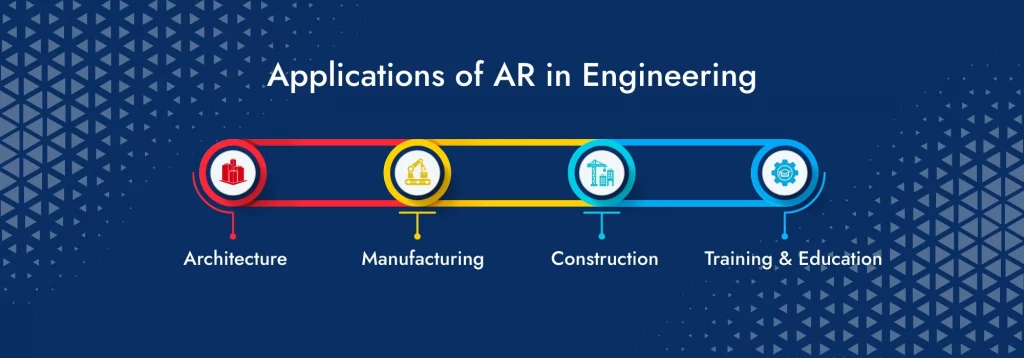

Applications of AR in engineering

Augmented reality (AR) is being applied in a wide range of engineering fields, including architecture, manufacturing, and construction. By transforming traditional approaches and enhancing various fields, AR has made substantial strides in the engineering sector.

Let’s understand the role of AR in engineering:

Architecture

Augmented reality in engineering is revolutionizing the way blueprints and designs are visualized. Using AR applications, architects can overlay digital models onto physical spaces. This allows them to see how the design will look and feel in the actual space, and to make necessary adjustments before construction begins.

Such a visualization not only aids in improving the design process but also facilitates better communication with clients and stakeholders by providing them with a realistic preview of the final product.

For example, an architect can show a client how their new home will look on their property, or they can collaborate with engineers to ensure that the design is feasible and meets all applicable codes and standards.

Manufacturing

AR is optimizing assembly line processes in manufacturing industries. Through AR-powered engineering solutions, workers receive step-by-step visual guidance overlaid onto the physical work environment.

This guidance significantly reduces errors, enhances productivity, and accelerates the learning curve for new processes or machinery. Workers can access critical information in real-time, ensuring accuracy in complex assembly tasks.

Construction

AR can be used to visualize the layout of construction sites. This can help to improve the efficiency of construction operations and to reduce the risk of errors. By using AR, engineers and workers can detect potential safety risks, such as underground utilities or structural weaknesses, before initiating construction.

This proactive approach not only minimizes risks but also ensures a safer working environment for on-site workers, significantly reducing accidents and project delays. AR can also be used to train workers in new construction techniques.

Training and education

Today, a large number of companies are leveraging AR to enhance training and education for engineers, For instance:

Boeing utilizes AR technology to train aircraft mechanics, offering digital experiences on wiring and repairing airplanes.

Siemens employs AR to train factory workers, guiding them through the assembly of complex machines with step-by-step interactive instructions.

Autodesk incorporates AR to educate students on engineering concepts, such as thermodynamics and fluid mechanics, providing an interactive learning environment.

Big brands led engineering innovation with AR

Let’s explore how leading brands have embraced AR, revolutionizing their engineering processes:

BMW: visualizing prototypes with precision

This popular automobile brand has integrated augmented reality software with its product data management system. This integration allows them to visualize and interact with true-to-scale prototypes, offering an in-depth understanding before finalizing designs for manufacturing.

BASF: leveraging digital twin technology for on-site precision

BASF has adopted augmented reality engineering solutions, through the implementation of digital twins. Engineers at BASF use AR to visualize planned pipelines on-site, ensuring accurate assessments of their intended functionality. AR aids in on-site monitoring, enabling swift identification of any design faults before they escalate into larger problems.

Lockheed Martin: enhancing aircraft assembly with ar integration

This global aerospace and defense company has embraced augmented reality to optimize its aircraft assembly processes. By integrating AR technology into their assembly lines, they can overlay digital schematics and instructions onto physical aircraft components in real time. This innovative approach reduces the likelihood of errors and improves overall efficiency while resulting in substantial cost savings.

Implementing an augmented reality engineering solution

The process of implementing an augmented reality engineering solution typically involves the following steps:

- Identify the specific engineering needs and goals for the business or project. What are the specific challenges that the business or project is facing? How can AR be used to address these challenges?

- Choose the right AR platform and hardware. There are a variety of AR platforms and hardware devices available on the market. It is important to choose the right platform and hardware for the specific needs of the business or project.

- Develop or customize the AR solution. Partner with a reputable AR solutions provider company like ViitorCloud to build a custom AR engineering solution.

- Deploy and train your workforce on the AR solution. Once the AR solution is developed, the users need to be trained on how to use it.

Starting augmented reality development

If you are considering implementing an augmented reality engineering solution, there are many companies like ViitorCloud that offer AR development services.

In the engineering field, AR is being used to revolutionize design, manufacturing, construction, and training processes. Engineers are increasingly leveraging AR to innovate and enhance their processes, leading to more efficient and effective solutions.

Conclusion

As the tech landscape continues to evolve, the future of engineering through AR presents an unparalleled horizon of possibilities. AR is not just a futuristic concept but a present-day reality shaping how engineers design, build, and innovate. ViitorCloud is at the forefront of this AR-led innovation in the field of engineering.

If you are looking for ways to improve the efficiency, accuracy, and safety of your engineering projects, consider building a custom augmented reality engineering solution that addresses these needs. Choose ViitorCloud as your partner for AR integration in engineering and embrace the future today!

Frequently asked questions

Augmented reality in engineering is revolutionizing designs, simulations, and safety assessments across the industry, transforming the way engineers visualize and interact with complex structures.

Applications of AR in engineering significantly enhance efficiency, accuracy, and safety, propelling the industry toward innovative solutions and streamlined processes.

Augmented reality in engineering optimizes processes by offering step-by-step visual guidance, reducing errors in complex assembly tasks, and improving overall productivity.

Applications or AR in engineering span across diverse sectors, from architecture to manufacturing and construction.

Engineers can get started with augmented reality by using existing AR platforms and hardware, or by developing their own AR applications.